ENGINEERING

Simulation instead of trial & error

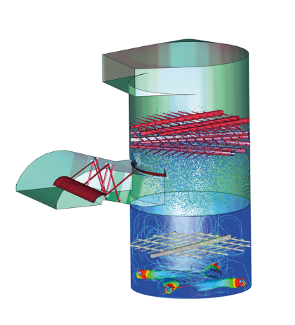

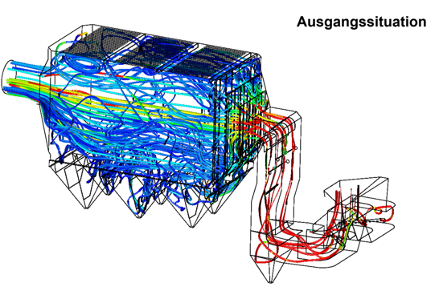

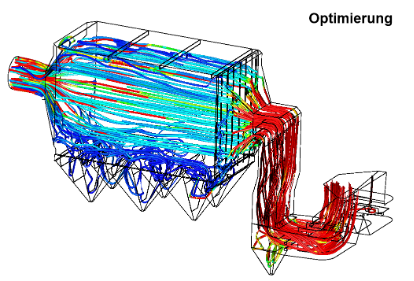

The analysis & flow optimisation of complex single-phase and multi-phase flows in industrial plants is our strength.

gridlab can identify technical risks and often achieve several significant improvement goals (e.g. product yield, energy savings, partial load capability) sustainably & simultaneously by using CFD-methods. Significant improvements can often be reached by moderate changes in the plant – as well as for new plant project or for enhancing the performance of existing plants.

High-End CFD-solutions for Flue Gas Cleaning

Especially in the optimisation of flue gas cleaning units gridlab has many years of experience – no matter if there are high flue gas volumes, high concentrations or temperatures.

Key processes and units:

|

|

gridlab – Doing things right

Process Engineering

Proving mass & energy balances,

Design &Engineering of flow charts

Support for technical specifications of key components, technical tenders, documentation, or similar

CAD-Engineering

Engineering of basic & detail drawings, piping, P&ID and steel construction.

Application fields

flue gas cleaning:

- tanker ships & large engines

- Thermal power plants

- Waste incineration & bio mass

Manufacturing industry (Steel, cement, refineries, pulp&paper and more)