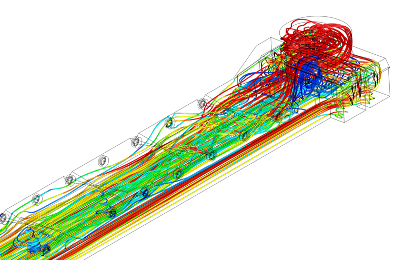

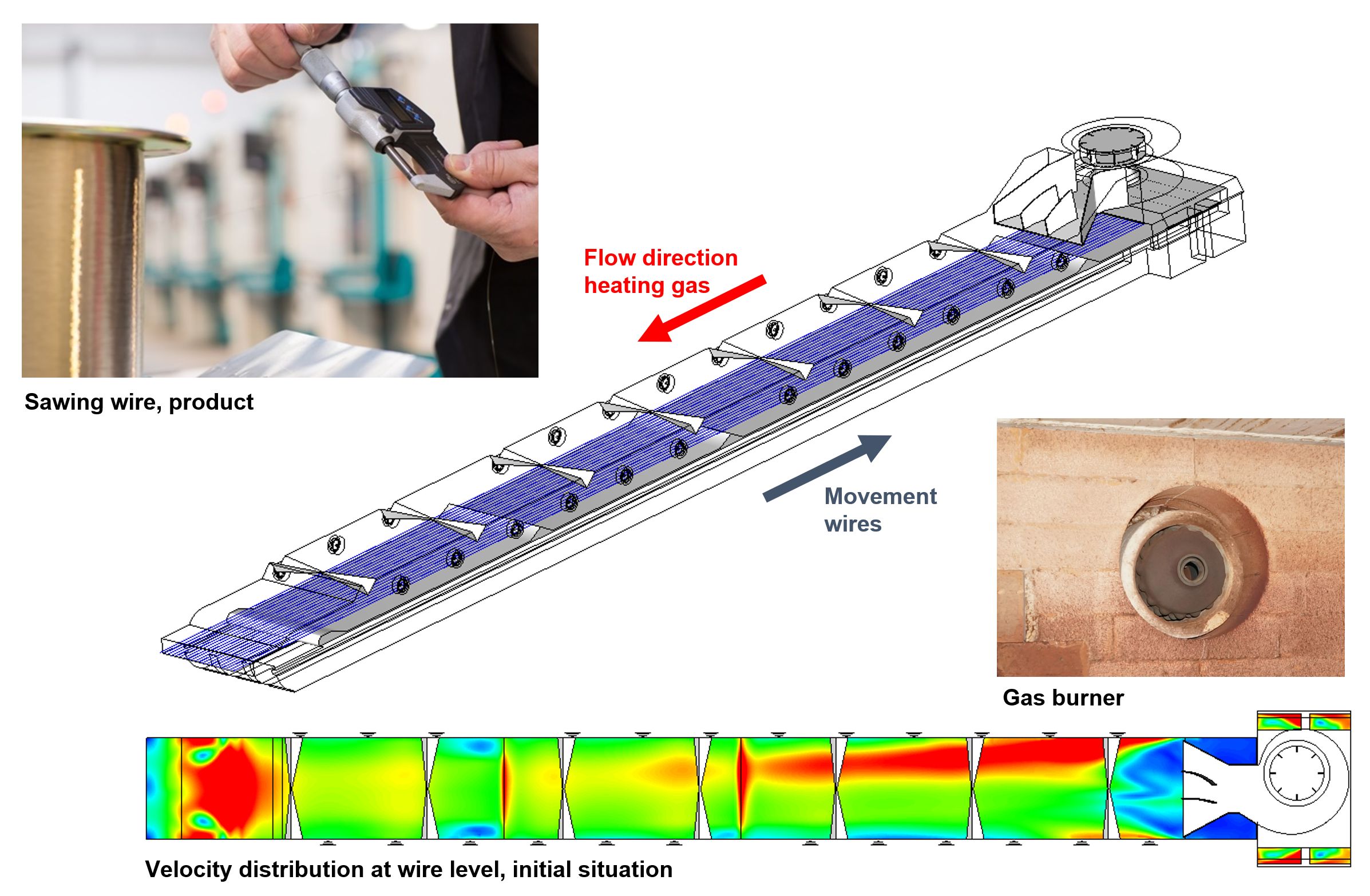

Flow optimisation Forced-Convection Kiln

Task: Detailed CFD flow modelling and optimisation of heat transport in the kiln improving product quality (special wires).

The sawing wires are a high-end product that has to very thin (ca. 100 µm) and very strong at the same time. They are needed for an efficient production of PV cells or silicon wafers in semiconductor industry. This kiln is a key unit in the wire production.

The sawing wires are a high-end product that has to very thin (ca. 100 µm) and very strong at the same time. They are needed for an efficient production of PV cells or silicon wafers in semiconductor industry. This kiln is a key unit in the wire production.

Results after optimisation:

- Significant higher product quality

- No thermal damages in the plant anymore

- Improved operational flexibility

- lmproved energy efficiency

- Fast revamping

Nomination Austrian Award for Information und Consulting in Austria!